CO₂ Recovery Plant Operation

The CO₂ Recovery Plant Operation is a crucial part of maintaining a sustainable and efficient system for recovering carbon dioxide (CO₂) from industrial processes. At RSV Gases, we provide in-depth operational expertise for the CO₂ recovery plant, ensuring seamless and continuous operation. Our advanced systems capture CO₂ from various sources, purify it to required standards, and compress it for reuse in applications such as beverages, welding, and medical industries.

How CO₂ Recovery Plant Works

The CO₂ recovery process typically involves several key stages to ensure the effective capture, purification, and reuse of CO₂:

1. CO₂ Capture

Source Identification: CO₂ is captured from industrial processes like fermentation, combustion (e.g., from power plants), and chemical manufacturing.

Capture Techniques: Using advanced gas separation technologies such as amine scrubbing, pressure swing adsorption (PSA), or membrane separation, CO₂ is extracted from the flue gas or exhaust gases.

2. CO₂ Purification

Filtration: The raw CO₂ undergoes filtration to remove impurities, dust, and particulate matter.

Purification System: Depending on the application (industrial, food, or medical), the CO₂ is purified using processes like distillation, pressure swing adsorption (PSA), or cryogenic separation to achieve the desired purity levels (99% or higher).

Dehydration: To remove any moisture, the purified CO₂ is passed through desiccant dryers or chilled to ensure dryness for sensitive applications such as medical or food-grade gases.

3. CO₂ Compression

High-Pressure Compression: Once purified, CO₂ is compressed to the desired pressure (typically 150–300 bar) for storage and transportation.

Storage: The compressed CO₂ is stored in high-pressure cylinders or tanks ready for distribution or use in various industries.

Cooling: The compressed gas is also cooled during the process to ensure safe storage and prevent over-pressurization.

4. Gas Distribution

On-Demand Supply: Once CO₂ is recovered, purified, and stored, it can be distributed to different departments or transported to customers using dedicated pipelines or cylinder filling stations.

Pressure Regulation: The distribution system uses regulators to control the flow and pressure, ensuring safe and efficient delivery for various applications.

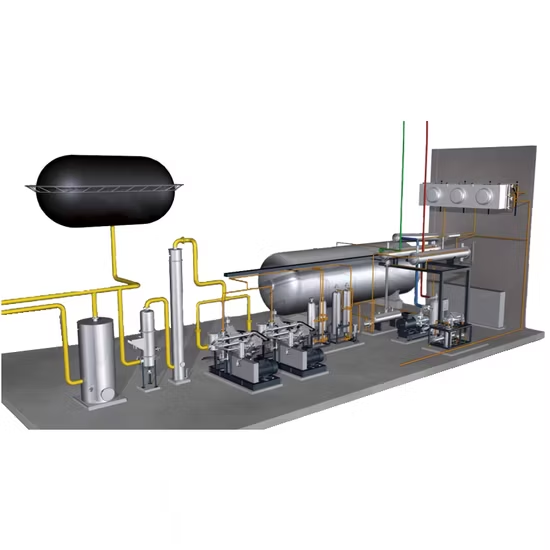

Key Components of CO₂ Recovery Plant

Gas Separation Units: For separating CO₂ from other gases.

Purification Systems: To remove contaminants and ensure high-purity CO₂.

Compression Units: To compress the CO₂ to the required pressure.

Storage Tanks: To store recovered CO₂ for future use.

Distribution Systems: Including pipelines, valves, and regulators for safe delivery.

Operational Maintenance

To ensure optimal performance and prevent system failures, regular maintenance is essential. Our operational team ensures the following:

1. Preventive Maintenance

Routine Inspections: Regular checks on compressors, valves, filters, and purification systems to prevent downtime.

Component Lubrication: Ensuring moving parts, such as compressors and pumps, are lubricated to reduce wear and tear.

2. Performance Monitoring

Efficiency Checks: Monitoring the recovery rate, purity levels, and pressure consistency.

Troubleshooting: Identifying potential issues early and performing repairs or adjustments.

3. Safety & Compliance

Safety Protocols: Ensuring all systems meet industrial safety standards, including pressure relief valves, emergency shutdown systems, and leak detection.

Regulatory Compliance: Ensuring the plant complies with local and international environmental regulations, including CO₂ emission standards.

Why Choose RSV Gases for CO₂ Recovery Plant Operation?

Expert Technicians: Our team consists of skilled professionals experienced in operating, maintaining, and troubleshooting CO₂ recovery systems.

Comprehensive Monitoring: Continuous monitoring of plant performance ensures efficiency and early detection of issues.

Tailored Solutions: We offer customized solutions based on the specific needs of your industry, whether it’s beverage carbonation, welding, or medical applications.

24/7 Support: We provide round-the-clock support to ensure your plant operates smoothly without any disruptions.

Sustainability Commitment: Our systems contribute to reducing carbon footprints by recycling CO₂ and minimizing waste.